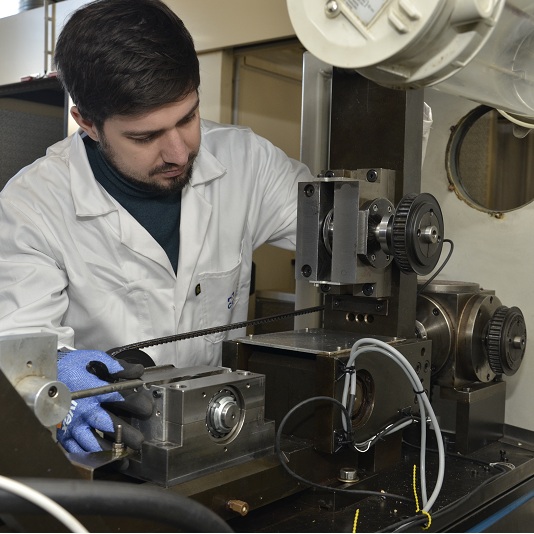

Cetim is upgrading one of its dual-disc test benches to provide manufacturers with more accurate data during testing.

Moving from photos to high-definition video! With the latest developments made by Cetim on one of its double-disc test benches, this equipment has moved from manual, occasional observation to automated, real-time digital monitoring.

This development makes it possible to analyse rolling contact fatigue, a key phenomenon in the sustainability of gears and bearings, with unprecedented accuracy, and to obtain essential data for the design of mechanical systems.

The dual-disc test bench reproduces the contact between two rollers subjected to high pressures and rotational speeds. It allows the progressive degradation of materials under repeated loads to be studied, friction coefficients to be measured and different combinations of materials, lubricants, roughnesses and geometries to be tested. By isolating the basic contact, it eliminates the disturbances present in tests on complete systems and facilitates the development of charts and predictive models of service life.

In order to offer manufacturers advanced features, the updated bi-disc test bench now incorporates sensors and a human-machine interface that enable continuous data collection and analysis at speeds of up to 3,000 rpm. The system also automatically detects critical thresholds (vibrations, temperature, incipient spalling) and can interrupt or extend tests without human intervention.

“It thus provides a comprehensive view of the evolution of defects, from the initiation of cracks to their propagation, and a detailed analysis of their morphology during the test,” says Louis Berger, who is in charge of this equipment at Cetim.

This test bench, which is also simpler and less expensive than full-scale tests, is a major economic asset for manufacturers, providing them with more accurate and comprehensive information on the behaviour of their products, enabling them to optimise their technical choices in the long term.